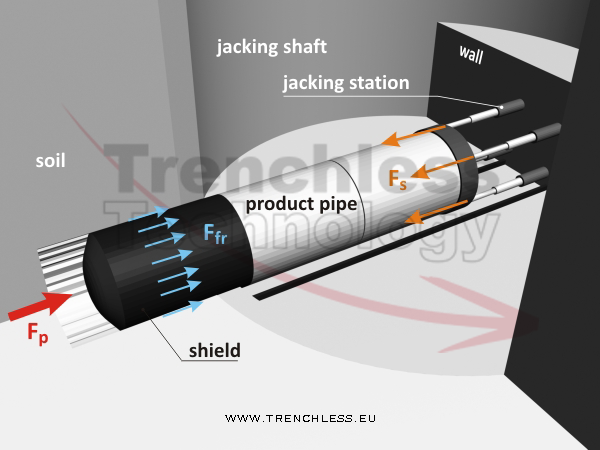

Pipe Jacking is a wide family of no-dig installation methods for the installation of underground pipes without digging up the surface. The pipe is installed by thrusting it into the ground behind a front shield, as the tunnel is excavated.

Depending on shield type, on excavation technique and on the method used for removing and transporting the debris, several different pipe jacking technologies have been developed since the invention of this method.

AUGER BORING, MICROTUNNELING and SMALL BORE TUNNELLING (SBT) are the given names that identify just some of the many methods for installing underground pipes by pipe jacking.

The main forces acting during the jacking stage

DIMENSIONAL RANGES AND MATERIALS

-

STEEL, concrete, GRP, CLAY, CAST IRON

-

LENGTH RANGES from 10 M (30 FT) UP TO 3.000 M (10.000 FT)

-

DIAMETER RANGES from 250 MM (10 IN) TO 3.500 MM (140 IN)

If you are interested in Pipe Jacking you will find of interest the following case history:

- INCLINED 72″ STEEL CASING INSTALLATION BY MICROTUNNELING

- INSTALLATION IN VERY HARD AND ABRASIVE ROCK OF A DN700 CAST IRON WATER PRESSURE PIPE

- DN1600 CONCRETE PIPE INSTALLATION BY MICROTUNNELING

You can also find articles and papers related to Pipe Jacking in the following sections of the website: